| Payment Type: | L/C,T/T,Paypal,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Model No.: Ap-900

V brand clamps roll forming and bending machine is used to form the V clamps from the steel strips and bend the V brand clamps according to the required V clamps diameter. The V bard clamps is also called Pipe Straps, used to support and fix the automobile exhaust tube and other tubes or profiles.

V band clamp roll forming machine is our new designed rollformer for the automobile exhaust tube clamping system. This rollformer for straps can produce the new style exhaust pipe hangers to support the exhaust tube. The monster stack clamps thickness is 1.5mm-2.5mm. The diameter of monster stack clamps can be adjusted different in one roll forming machine line by adjusting the bending radius.

exhaust pipe hangers rollformer adopts both the roller forming designing and the roller bending designing, together to form a new developed clamps products.

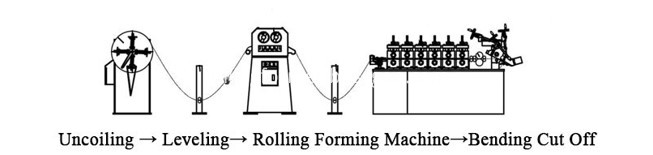

Clamps rollingforming machine including working process like this:

First the proper width raw material steel strips be decoiling from the decoiler system. The Decoiler system can be manual decoiler system , or the hydraulic decoiler system, capacity 3 tons is OK.

The feeding galvanized steel strips width is according to the pipe strps width.

Second the material strips will be feed into the livelling system to be straighten and flatten. There will be 5 rollers on the leveller sytem for straignten the strips.

Third the strips material will be feed into the main roll forming machine body. There are 7 stations for roller forming the clamps.

Forth, the straight formed profiles will be bent by the rolling system to form the O ring hoop at the right radius to for the right clamps.

At last, the hydraulic cutting system cut the final formed clamps after the ring hoop is formed correctly.

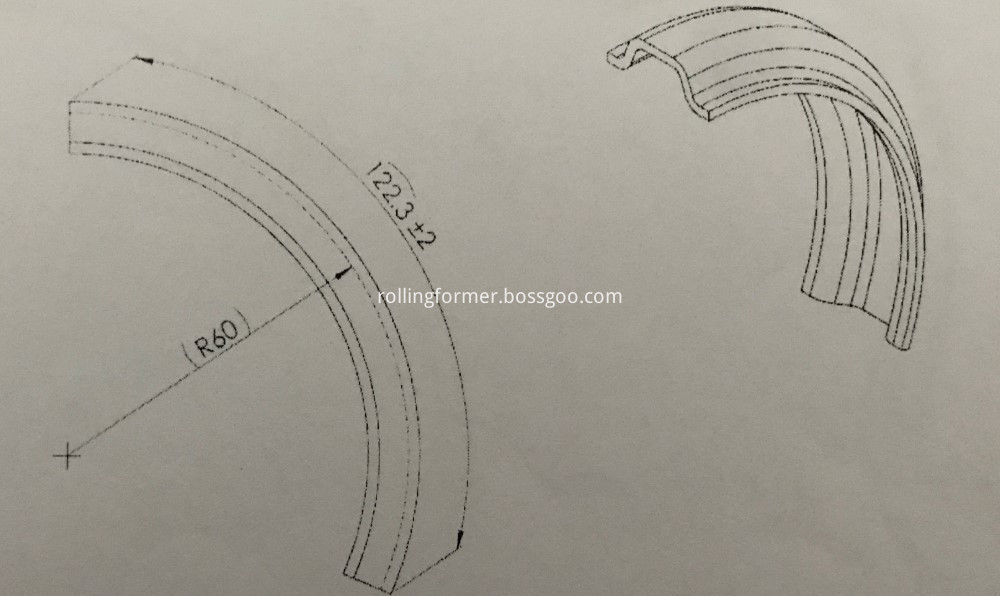

Below are some pictures of the finished products:

Below is the drawing of the V band clamp for your reference:

The V band clamp is used for the supporting of the car exhasut tube. It is small profile roll formed and bent. So the rollformer machine and bending machine need high precision!

This is the V band clamp rollformer machine 's high requirements from other C purline machine, Z purline machine, CZ purline machine, Sigma purline machine and M purline machine.

Clamps rollingformer including below parts:

Decoiler,Leveller,PLC controling system,Main roll forming body, Rolling bending system, Cutting system, Hydraulic station.

V Band clamp roll forming machine working process:

Uncoiling →Leveling→→Rolling Forming Machine→ Bending.cut off

Equipment Floor Area:4*1*1.5m(L*W*H)

Feeding Direction: From Right to Left

Voltage:3 Phase, 415V,50Hz

Air Supply: Flow Rate:0.5m/³min; Pressure: 0.6MPa

Hydraulic Fluid:46#

Gear Oil: 18# Hyperbolic gear oil

Size of the raw material steel strips of the V band :

Width of Strip ≤80mm

Thickness of Strip ≤ 2.5 mm

Material of Strip: Stainless Steel

Total Power: approximately 24.5KW.

Ring diameter range:120~350 mm.

Whole rollformer line of the V band clamp machine including below parts:

NO Equipment Name

Quantity

(KW) Motor Power

1 automatic Un-coiler

1 3 2 Precise leveling machine

1 1.5 3 Roll Forming Machine

1 15 4 bending module.cut off

1 5

Brand of every part of the V band clamp rollformer line:

NO Equipment Name

Manufacturer

1 PLC

OMRON

2 HMI

OMRON

3 Electric Elements

Schneider/OMRON/ Keyence/ Siko

4 Bearing

Timken.Schaeffler

5 variable frequency motor

SIEMENS

6 Rotary encoder

OMRON

7 Digital position display

SIK

The whole line of V band roll forming machine is well designed, with many innovative designing solutions, the main goal is to make a working stable,

and high precision mill to produce high quality, with high precision V band.

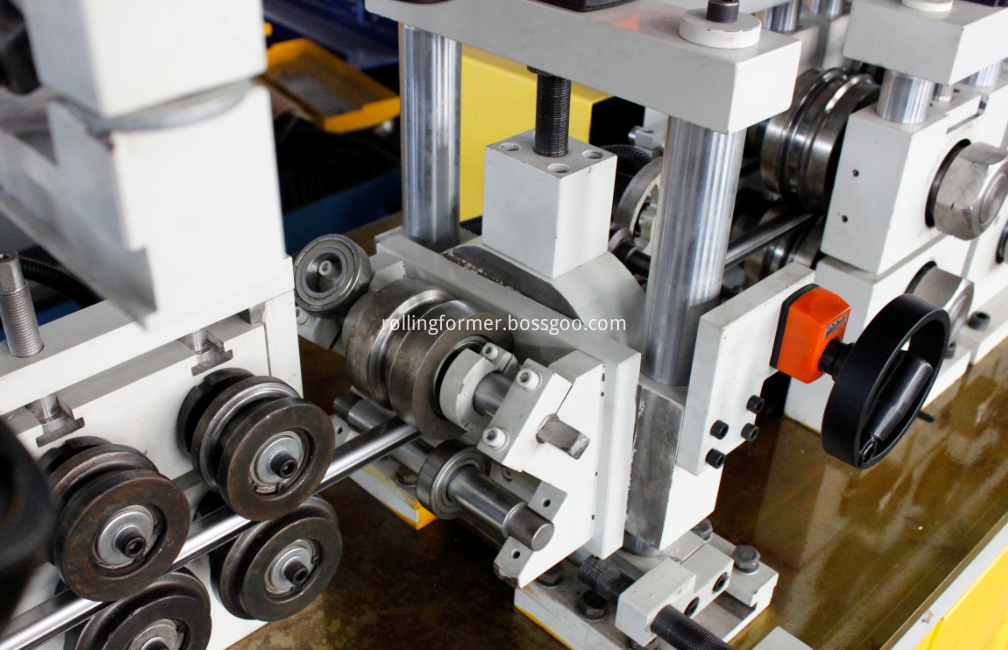

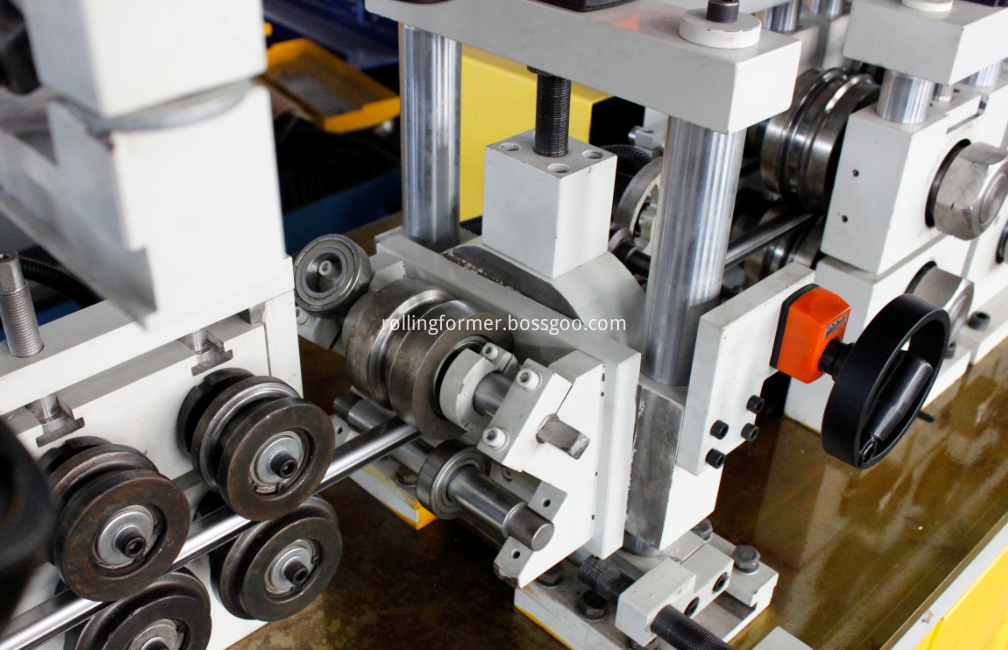

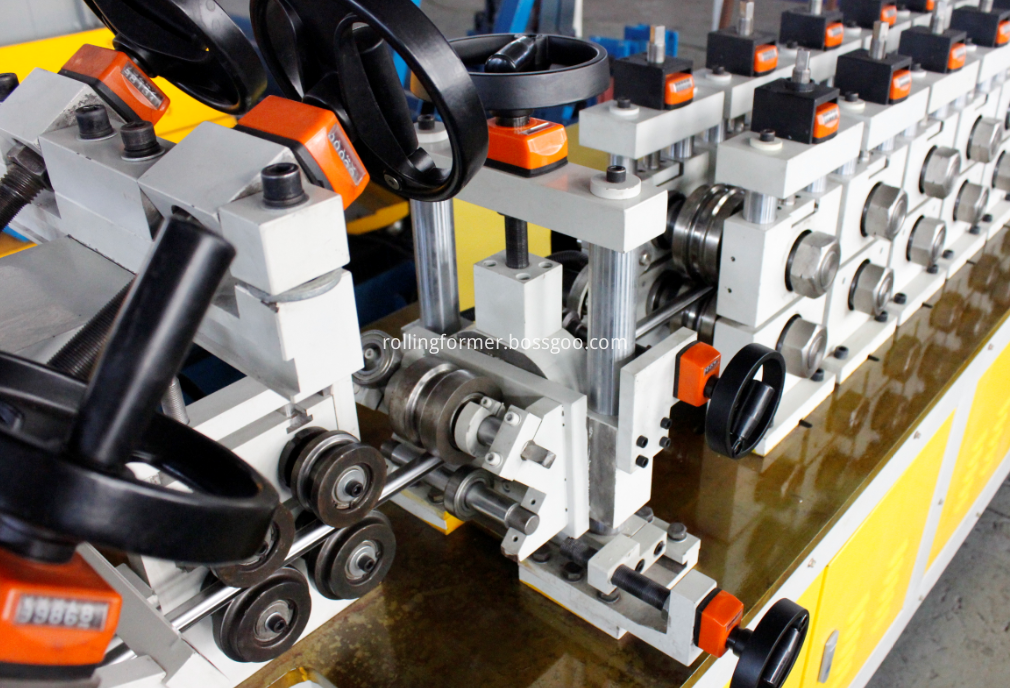

Below is the introsuction of the Main roll forming machine.

NO NAME SPECIFICATION 1 Strips thickness

≤ 2.5 mm

2 Roller station

8 ROWS

3 Power Supply

Can be made according requirement 4 Machine structural

Memerical archway

5 Roller distance

200mm

6 Roller material

42CrMo

7 Shaft diameter

45mm

8 Main forming machine body

350 H steel

9 Electric

Schneider/Omron Keyence/Siko

10 Bearing

Timken, Schaeffler

11 Variable frequency motor

Siemens

12 Rotary encode

Omron

13 Cutter Standard

GCr12

Accorfing to the V vand clamp diameters size, this rollformer and bending machine can produce different size V band clamp, by quick changing and adjusting the rollers to acheive it.

This quick change structure save much time and humar labor, and making the V band rollerformer with high capacity for different size V bands.

If you want to replace the model you can use the crane to replace it

Pass pitch: 200mm

Memorial archway structural:Precision guide column bracket

Roll shaft diameter:45mm

Roller Material: 42CrMo

Also this machine line is designed with below functions:

1. Guide device: The coil is accurately introduced into the first forming wheel with the digital position display.Adjustment range: 10~80mm

2. Lubrication system: Lubrication device use can reduce the friction processing products and roll

3. Correction of the head/Turks head: This Turks head with design well , ensure the V band profile straight after rolled forming.

4. Length detection:The measuring wheel moves over the profile, the rotary pulse generator controls the pulse signal, and the control unit issues a cut-off command according to the required profile length

5. Guarding:The protective cover prevents the handle from reaching the host's tool and plays a role in reducing the noise. In the automatic operation mode, the full transparent observation process cannot be opened by the magnetic locking of the machine

If you want to know more details of every part of this high precision V band rollformer machine line, please feel free contact me, i will send you the offers with the price and specifications, and the machine running videos.

Product Categories : Purlin Rollforming Line > U Supporting Purlin Bracket Rollforming Line